At RSIPL, our vision for sustained growth and technological advancement propels us towards a transformative future in the realm of sponge iron manufacturing and integrated steel production. We are excited to outline our proposed expansions, aiming to augment our capabilities and reinforce our position as an industry leader committed to excellence and innovation.

Enhanced Sponge Iron Manufacturing :

We are on the verge of establishing a formidable production facility, featuring a state-of-the-art 1 x 350 tonnes per day (TPD) sponge iron kiln. With an estimated annual production capacity of 105,000 tonnes, this addition will complement our existing 4 x 100 TPD kilns, leading to a substantial increase in our total sponge iron output to 225,000 tonnes per annum (TPA).

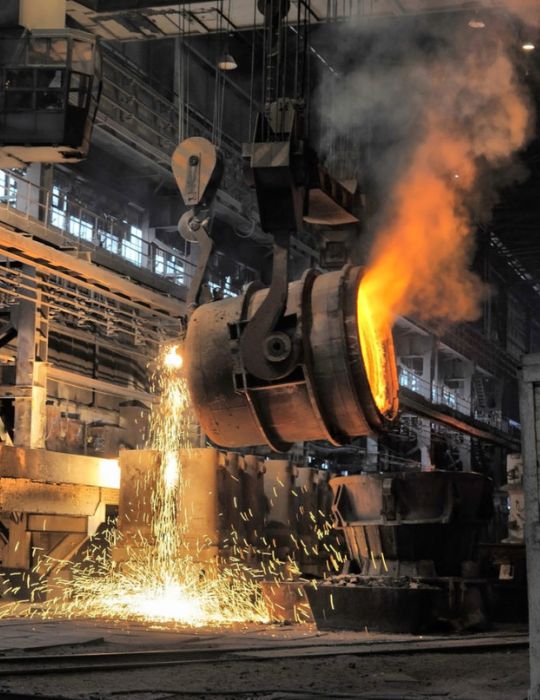

Steel Melting Furnace :

In line with our diversification strategy, we plan to introduce an advanced configuration of induction furnaces, each with a capacity of 4 x 15 tonnes per hour (TPH). This addition will significantly bolster our steel production capability, enabling the manufacture of 180,000 tonnes per annum (TPA) through 10 heats per day.

Continuous Caster for Billet Production :

Our proposed units of continuous caster machines, configured at 3 x 6/11-meter radius, are aimed at expanding our billet manufacturing capacity. These units will enable us to produce 176,400 tonnes per annum (TPA) of high-quality billets, ensuring seamless alignment with our expanded sponge iron capacity.

Rolling Mill Facility :

In a bid to further diversify and meet market demands, we plan to introduce a modern rolling mill with a production capacity of 150,000 tonnes per annum (TPA). This unit will enhance our capabilities to deliver various steel products with precision and quality.

Slag Grinding Unit :

In our commitment to maximizing resource utilization, we are proposing a slag grinding unit with an annual capacity of 40,000 tonnes. This unit will enable us to efficiently process slag, contributing to environmental sustainability while extracting value from by-products.

Captive Power Plant Expansion :

Expanding our commitment to sustainable operations, our proposed expansion includes a Captive Power Plant with a Waste Heat Recovery Boiler (WHRB) generating 16 MW and an additional 14 MW from an Atmospheric Fluidised Bed Combustion (AFBC) system. This 30 MW capacity will cater to our in-house energy needs, supporting our expanded production facilities.

At RSIPL, these future endeavors represent a holistic commitment to excellence, sustainability, and technological advancement. Our ongoing efforts align with our core values of responsible industrial practices and a steadfast dedication to environmental stewardship while positioning us as a frontrunner in the steel manufacturing landscape.